Hybrid power plant for a pig breeding center in Spain

Intervention type

Pre-study, study, commissioningCustomer

MazanaDate of completion

Location

Huesca, SpainAbout the installation

The group of companies Mazana, a national leader in pig production, has entrusted CRE Technology with the hybrid project combining its diesel generation power plant with the photovoltaic power plant at its facilities in Castelflorite (Huesca, Spain). Committed to the environment and decarbonization, both companies have designed a system that reduces diesel consumption and pollutant emissions

1. Context

The growing demand for sustainable and efficient energy solutions has led to significant progress in the integration of renewable technologies and conventional energy sources. In this context, CRE Technology has developed an innovative hybrid solution, which combines multiple sources of electricity generation in a flexible and efficient method. This system not only optimizes energy use, but also contributes to the reduction of operating costs and pollutant emissions, making it possible to manage available energy resources more efficiently.

Hybrid electrical systems is a key trend in many industries, particularly in areas where renewable energy sources, such as photovoltaics and wind turbines, need to be complemented using traditional systems, such as gensets. Without a proper hybrid solution, these systems can operate inefficiently, which can result in increased fuel consumption, high operating costs and reduced reliability of power supply.

CRE Technology's hybrid solution allows for a smooth integration of various energy sources, adapting to the specific needs of each customer. Thanks to its modular and highly flexible design, the solution can be expanded and customized according to the particular energy requirements of each installation. In addition, this state-of-the-art technology not only optimizes the use of resources, but also ensures the reliability and stability of the electrical system, even in adverse conditions or in case of communication failures between control equipment.

The Castelflorite pig breeding center, located in the province of Huesca, was inaugurated at the end of 2024 and has established itself as one of the most modern and advanced facilities in its field. With a capacity to host 3,000 pig mothers and a production capacity of more than 60,000 piglets per year, the core integrates a series of state-of-the-art technological systems, designed to guarantee animal welfare and optimize production.

In addition to its production capacity, the facility stands out for its commitment to sustainability and the reduction of its environmental footprint.

Innovative technologies enable strict control environmental and sanitary conditions, reducing the risk of cross-contamination between animals and limiting the risk of disease. The integration of these technological solutions is essential to improve operational efficiency and ensure a healthy environment for the animals, a key factor in their development and productivity.

In a context where the agri-food industry is moving towards more sustainable models, the Castelflorite Center represents an example of innovation, integrating best practices in animal welfare and eco-responsibility.

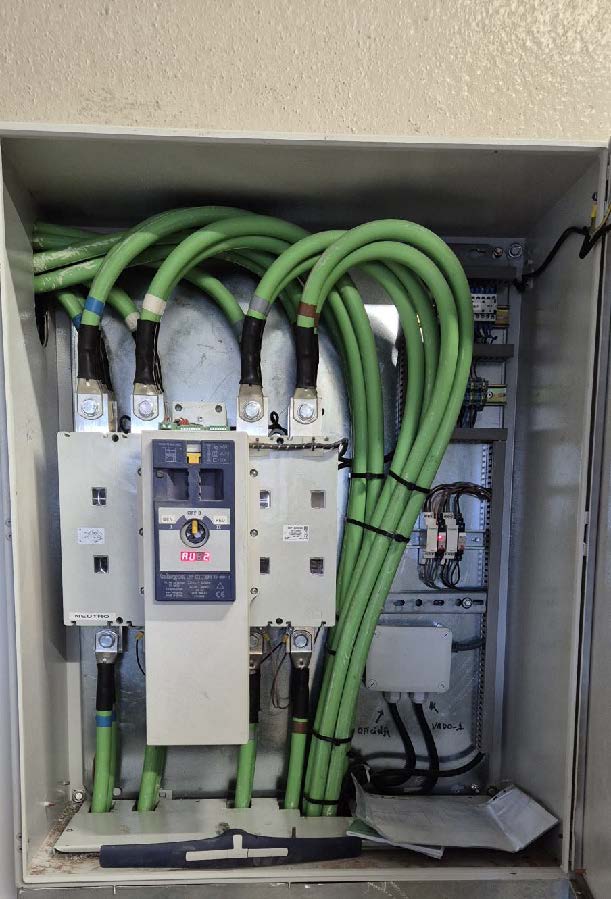

To ensure the proper operation of these facilities, due to their dependence on electrical power and the absence of a grid connection, two gensets have been installed for continuous 24/7 operation, one of them serving as a back-up to the main genset.

The gensets, manufactured by Grupos y Generadores Monzón, the main genset has a power of 300 kVA and the emergency genset 500 kVA, and they have frequency and voltage regulation.

In anticipation of connection to the power grid, scheduled for the end of 2025, Grupo Empresarial Mazana has installed a 220 kW photovoltaic power plant, with a nominal power of 200 kW, equipped with 2 Huawei inverters and Longi PV panels, to support the power grid and reduce electricity consumption. The installation of the photovoltaic station was executed by the company AMB Greenpower, which actively collaborated in the integration of the photovoltaic station with the hybrid solution developed by CRE Technology.

2. Problems encountered by the customer

The absence of a connection to the electricity power grid means that the main generator has to run continuously, which means:

- High diesel consumption, leading to significant operating costs.

- Frequent tank refills, requiring regular logistics.

In addition, the entry of vehicles into the center represents a health risk for the animals, increasing the risk of contamination and the spread of disease. It is therefore essential to limit these movements as much as possible.

Given these constraints, reducing diesel consumption was a priority for the customer. This led CRE Technology to develop an advanced control system, which allows the hybridization of the photovoltaic (PV) power plant with the gensets.

The solution we provided

After an in-depth study of energy integration, CRE Technology proposed a solution guaranteeing complete hybridization of the photovoltaic power plant with the gensets.

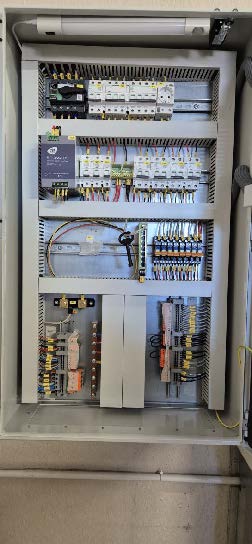

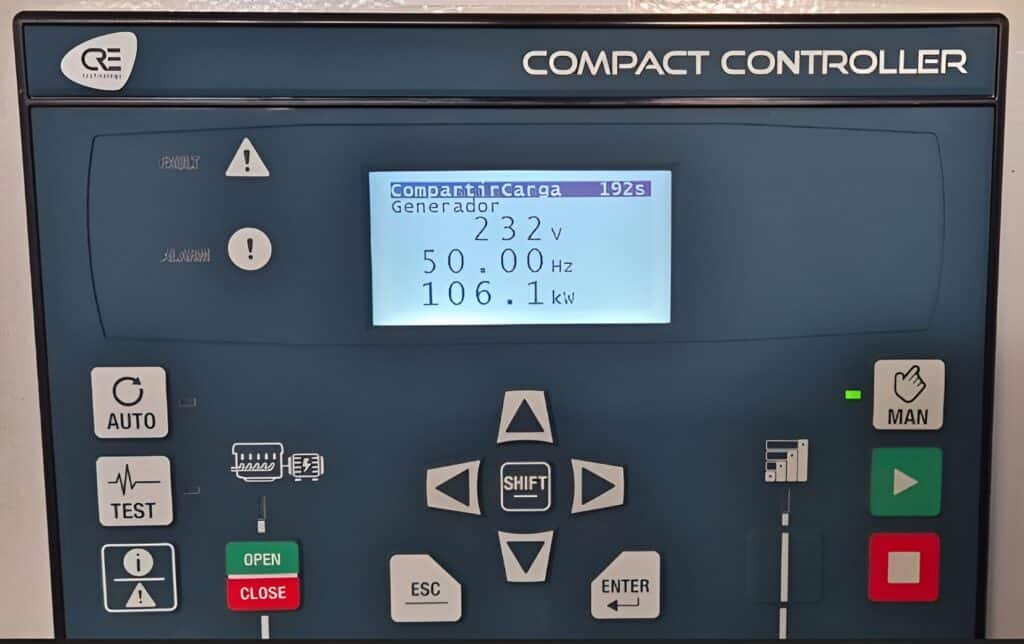

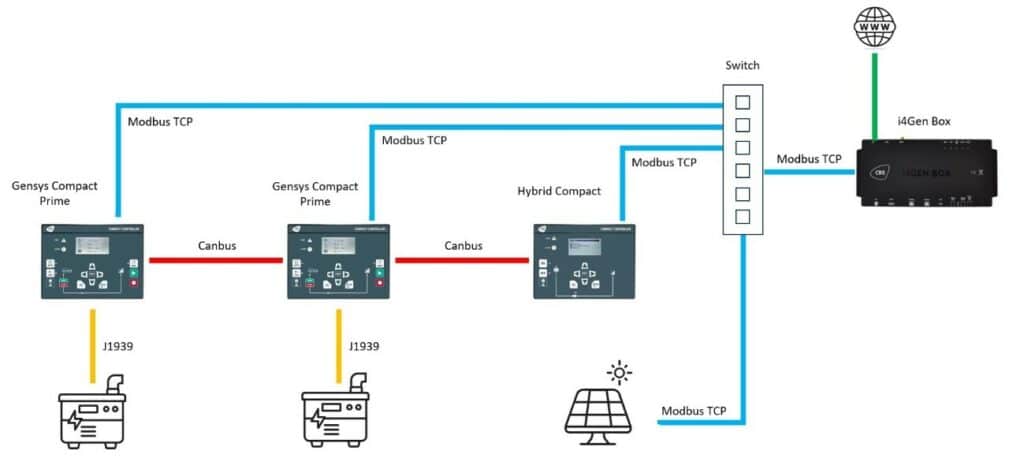

This solution is based on the use of control equipment from the COMPACT range, ensuring the management of both the gensets and the photovoltaic inverters.

In addition, a remote access module was installed, enabling real-time supervision of the power plant and sending of alerts in case of anomalies.

1. GENSYS COMPACT PRIME module – Genset management

A GENSYS COMPACT PRIME module has been installed for the management of generating sets, with the following functionalities:

- Automated engine start & stop: Simplifies the process of start/stop generator operation.

- J1939 CANbus communication: Ensures integration with electronic engines, enhancing performance monitoring and control.

- Generator protections: Includes mechanical and electrical protection to ensure reliable and safe operation.

- Parameter monitoring and visualization: Allows simple visualization and control of mechanical and electrical parameters.

- Synchronization capability: Allows synchronization of up to 32 gensets, with the grid, batteries, photovoltaic panels or wind turbines, ensuring efficient energy management.

- Load sharing (kW/kVAr): Features load/unload ramp transfer management for optimized power distribution.

- Dynamic generator management: Automatically adjusts the number of generators in operation based on load variations and photovoltaic or wind production. This feature relies on advanced CANbus communication with other hybrid controllers, guaranteeing a constant backup power supply.

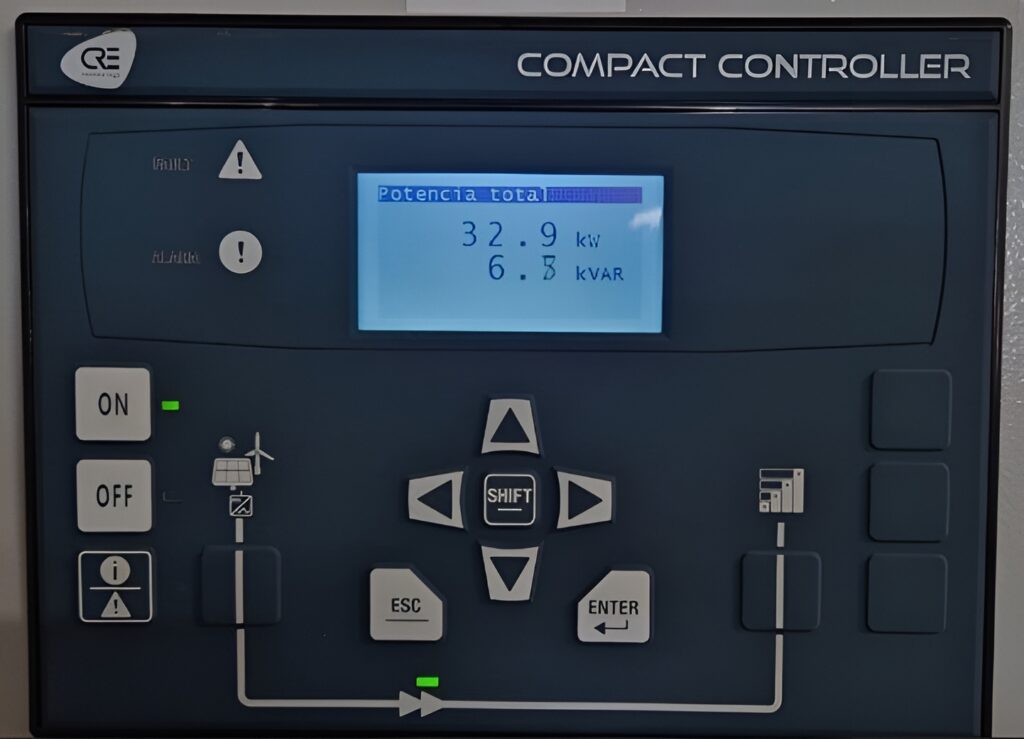

2. HYBRID COMPACT module – Photovoltaic and wind inverter management

A HYBRID COMPACT module has been installed for the management of photovoltaic inverters via the Huawei SmartLogger 3000, with the following functionalities:

- Flexible inverter control : Capable of managing either a single photovoltaic or wind turbine inverter, as well as simultaneous management of several inverters via a proprietary centralization device.

- Extensive communication compatibility: Supports ModBus TCP & RTU protocols (with RTU adapter) for a wide range of inverters, including: ABB, Afore, AP Systems, Canadian Solar, Danfoss Solar, Delta, Deye, Fronius, Goodwe, Hoymiles, Huawei, Kaco, Outback Power, Qcells, Schneider, Solax Power, Solis, Sungrow...

- For Sunspec-compatible inverters, recognition is automatic, without the need for ModBus table configuration.

- For non-Sunspec inverters, a configurable ModBus table is available.

- Parameter monitoring and display: Allows acquisition and display of inverter electrical parameters, either via ModBus TCP/RTU or using the product's own voltage and current inputs for redundancy and accelerated data acquisition.

- Photovoltaic and wind power limitation management: Adjustment of production power according to application requirements, in particular for:

- Maintain a minimum power on the generating sets

- Comply with grid setpoints

- Limit batteries charging current

- Reactive power control : Enables reactive power management of photovoltaic or wind inverters via :

- A configurable fixed power factor

- Sharing reactive power between different energy sources

- Safety of production:

- Immediate shutdown of photovoltaic or wind production in the event of reverse power to the generators, in order to maintain production.

- Integration of manual control of the inverters' production relay.

- Communication loss management: In the event of communication loss with the inverter:

- The controller can open the inverter's production relay.

- The generating sets switch to droop mode to ensure continuous power supply, then return to isochronous mode once communication is restored.

- Electrical protection of inverters: Guarantees the safety and longevity of equipment.

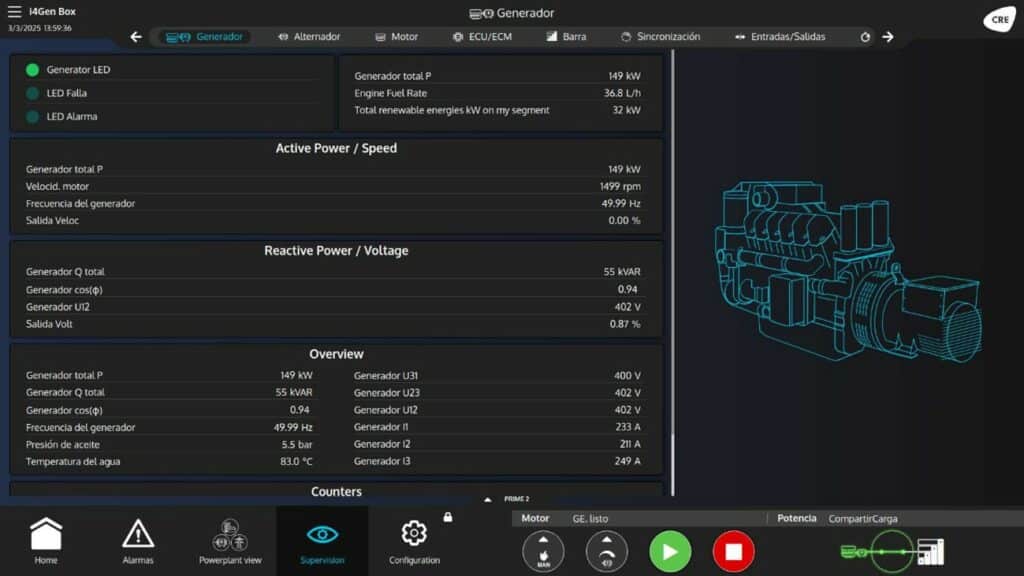

3. I4GEN BOX module – Supervision and remote access

An I4GEN BOX module has been installed to enable remote supervision and management of the installation, with the following functionalities:

- Automatic display of a single line diagram of your power plant: Simplifies management and monitoring of up to 40 energy sources.

- Time-stamped eventlog : Stores the last 500 events, alarms and faults, with several filters for easy diagnosis.

- Production history curves: Data retention up to 30 years for detailed performance analysis.

- Universal connectivity: Internet access via Wi-Fi, Ethernet (WAN) or 4G (SIM card), guaranteeing supervision in all circumstances.

- Automatic IP address configuration: Quick and easy access to the power plant's multiple controllers.

- Automatic network time synchronization: Applicable to all controllers to ensure data consistency.

- Secure remote access via ZOHO Assist©: Enables monitoring, configuration, and control of equipment, wherever you are.

- Detailed e-mail notifications: Automatic alerts in the event of an alarm or fault.

- Built-in GPS location: E-mail notification if generators are moved.

- Fully customizable display interface: Supervision pages can be customized to meet specific customer requirements.

- Customization of the customer interface: Display of the customized logo in the header, on the home page, and on the startup screen.

4. Communication management between generating sets and inverters

To ensure optimal control of energy production between the generating sets and photovoltaic inverters, a communication topology based on CANBus and Modbus TCP has been implemented. This architecture enables efficient management of power flows and guarantees a balanced distribution of the load between the different energy sources.

In this way, the power produced, such as active and reactive, by the gensets and the PV inverters can be controlled, allowing an efficient load sharing between these different energy sources.

In case of loss of CANBus communication between the controllers, the power plant will operate in droop mode, allowing the gensets to continue to run in parallel with the PV inverters.

The system also incorporates protection against reverse power to the gensets. If there is a risk of reverse power, PV production is deactivated to prevent the generators from shutting down, which could cause a loss of voltage in the system.

The i4Gen Box module allows generating kW and kVAr production curves of both the gensets and the PV power plant. The following image shows the generation profile of this application.

Thanks to the curve stacking option, it can be clearly seen how the PV inverters (yellow curve) generate more power than the genset (blue curve) during sunny hours.

The hybrid solution developed by CRE Technology offers the following advantages:

- Modularity and scalability: A solution that can be adapted to customer needs, offering an excellent ratio between functionality and cost.

- Advanced hybridization management: Enables efficient control different power generation sources, such as the grid, gensets, PV inverters, battery storage, and wind turbines, in any quantity or combination.

- Integrated control sequences: Includes predefined sequences that eliminate the need for a PLC, guaranteeing energy production even in case of communication loss between control equipment. This approach also reduces commissioning time thanks to simplified configuration.

- Remote supervision: Enables real-time monitoring from any device, with the option of two-factor authentication and alerts in case of anomalies.

- Optimized installation costs: Thanks to the capability of PV inverters to produce reactive power in all four quadrants, the installation of a capacitor bank becomes unnecessary, reducing the global cost of the installation.

- Reduction of fuel consumption and polluting emissions: Optimizing the use of renewable sources reduces fuel consumption by up to 50%, as illustrated in the following images, highlighting the impact of photovoltaic production on diesel consumption.

Conclusion

According to this article, the hybridization of different energy sources not only represents an innovative solution for power generation, but also offers numerous technical and economic advantages.

By combining renewable energy sources, such as solar and wind power, with conventional generation systems, it is possible tooptimize plant performance and reliability. This allows our customers to significantly reduce installation and maintenance costs, while making optimum use of available energy resources, depending on environmental conditions.

This hybrid approach also has a direct impact on sustainability, as it helps to reduce polluting emissions by reducing dependence on fossil fuels.

It thus offers a dual advantage: both economically for users, and ecologically, by promoting a more responsible and environmentally-friendly energy consumption model.

With this in mind, the deployment of hybrid technologies is a key strategy for supporting the energy transition, helping to mitigate the effects of climate change on a global scale.

This type of hybrid application is therefore not only aimed at optimizing resources and reducing costs, but also actively participates in building a greener, more sustainable future for future generations.

Related products

GENSYS COMPACT PRIME

The GENSYS COMPACT PRIME is designed for advanced management of multiple generators in power plants, while offering interoperability with other types of energy sources for more complex systems.

Add to quoteHYBRID COMPACT

The HYBRID COMPACT is designed to efficiently manage photovoltaic or wind inverters, while ensuring optimum integration with other energy sources and management systems.

Add to quote