Combined heat and power (CHP)

Intervention type

Commissioning, application engineeringLocation

GermanyApplication description

CHP power plants require high flexibility and a high level of performance from the controllers.

Constraints in terms of regulation and fuel require the engine to be operated according to specific and adapted sequences. The power plant presented here consists of 2 x 100kVA gas generators on mains paralleling using a series of micro-turbines.

Gas generating sets are equipped with GENSYS 2.0, which manages paralleling and:

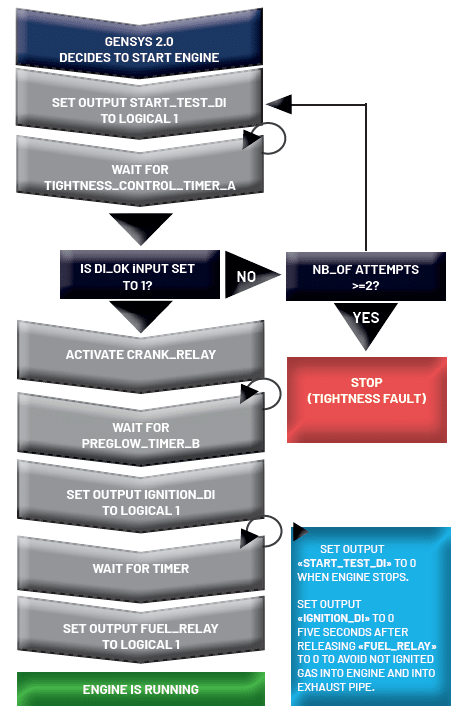

Specific gas engine start/stop sequences :

- Ignition and preheating

- Idle speed sequence

- Tightness control and gas emptying

Power management:

- Dedicated ramp up/down

- Active power and reactive power control

- Paralleling protections

- kW Base load mode depending on temperature & gas flow

CRE TECHNOLOGY has been able to meet the technical specifications required in terms of gas engine and cogeneration control thanks to its highly integrated solutions and their ability to include specific sequences.

Products installed

- 2 x GENSYS 2.0

Engine starting sequence

Related products

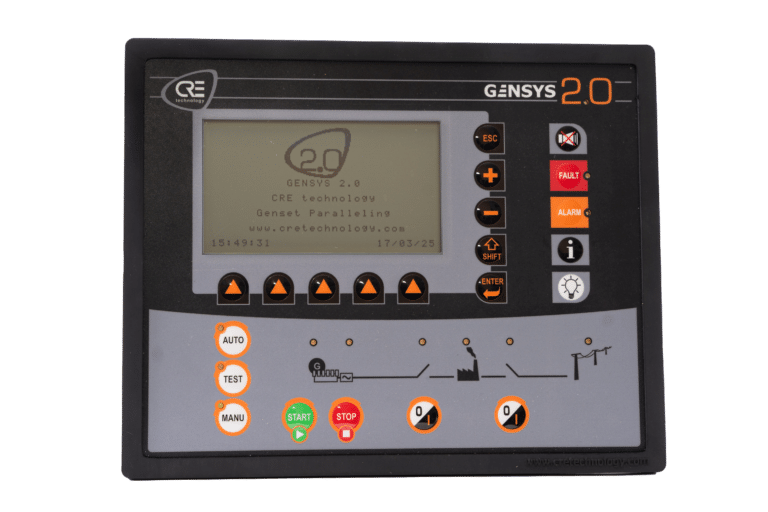

GENSYS 2.0

The GENSYS 2.0 is a complete and compact controller « all-in-one » including engine management, synchronization, active power and reactive, control up to 32 generators or a single generator in parallel with mains

Add to quote